Ductility

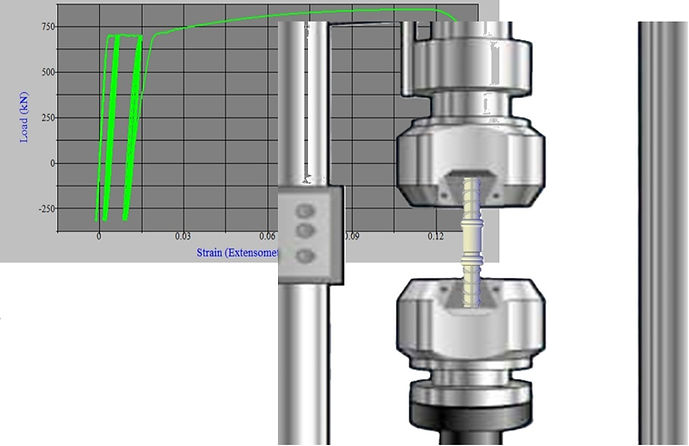

McCalls Rebar Coupler were tested to high performance

A good rebar coupler should perform as continuous rebar. Thus the splicing strength should be strong and complied with the full ductility of the reinforcing steel.

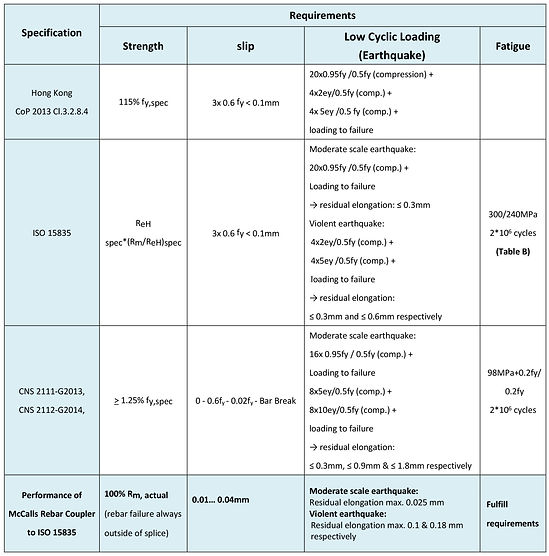

Table A

Diagram of Full Ductility of Reinforcing Steel

The transfer of ductility

The above diagram illustrates how a rebar coupler with insufficient capacity will hinder the utilization of the full ductility of the rebar. The stress and strain properties of most rebar heats exceed the minimum requirements of the standards as fy,spec (fy,nom) and Agt,nom. If the prescribed capacity of the coupler (xn% * fy,spec) is too low, the prescribed strength may be achieved, but the usable elongation will be limited considerably. This might be affect the design which requires the full ductility of the reinforcement

Notes:

-

fy,spec, ReH - specified (or nominal) yield strength;

-

fu, spec, Rm,spec - specified (or nominal) tensile strength;

-

Rm, act – actual tensile strength (real rupture strength) of rebar

-

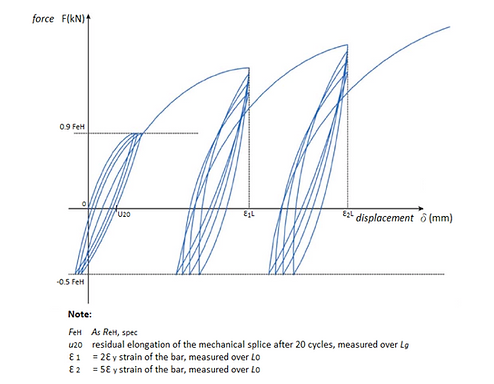

2ey – 2 times the calculated strain (assuming E = 2 x 105 Mpa) under strain control measured by an extensometer placed on the free length of the bar;

-

5ey – 5 times the calculated strain (assuming E = 2 x 105 Mpa) under strain control measured by an extensometer placed on the free length of the bar;

Table B

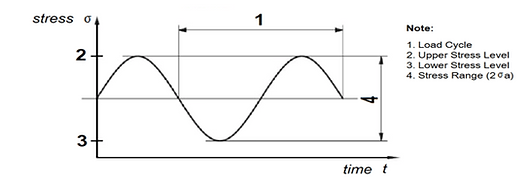

Load Cycle Diagram for The High-Cycle Fatigue Test

(ISO 15835)

Table C

Load Cycle Diagram for The Low-Cycle Fatigue Test

(ISO 15835)